This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The Most Rigorous Testing for the Most Demanding Applications

Strictest validation requirements for unsurpassed global quality.

Casar and Oliveira Made in the USA crane rope product lines go through a battery of production acceptance tests that confirm product conformance to WireCo’s stringent internal requirements, which far exceed the industry specification requirements. The ropes produced at our Sedalia manufacturing facility exceed the specification standards in EN 12385-4 for steel rope products by tightening diameter tolerances, increasing minimum breaking forces, and ensuring that diameter reduction under load and angular rotation under load are controlled at much tighter tolerances than the rest of the industry.

In addition to product acceptance testing, WireCo conducts performance validation tests to confirm that Made in the USA crane ropes perform to the same expected performance levels as products from our manufacturing facilities in Portugal and Germany. WireCo uses cyclic bending over sheave and crossover fatigue testing to simulate failure modes in the field, in addition to real-life load cycling of our most critical crane products on actual cranes.

Each diameter and each product line must successfully go through the required production acceptance and performance validation tests, and be approved by the Global Crane Team, prior to being released for production and sale to our customers. When purchasing a Made in the USA Oliveira or Casar crane rope, you can be assured that WireCo has thoroughly vetted the physical properties and performance behaviors of our mission-critical crane ropes.

Our Expanded Product Line

Category 1 rotation-resistant and high-performance eight-strand products manufactured at our facility in Sedalia, Missouri.

Overview

- Temperature range of use: –50°C to +75°C (-58°F to +167°F)

- Temperature range of use for option PPI: -50°C to +80°C

- Option PPI – only available for diameter ≥ 13mm

- Suitable for multilayer spooling in Lang‘s lay

- Available in ordinary lay and Lang‘s lay

- Available in right-hand and left-hand

- Available in galvanized and ungalvanized

Properties

- Swivel

- Lubricated

- Compacted

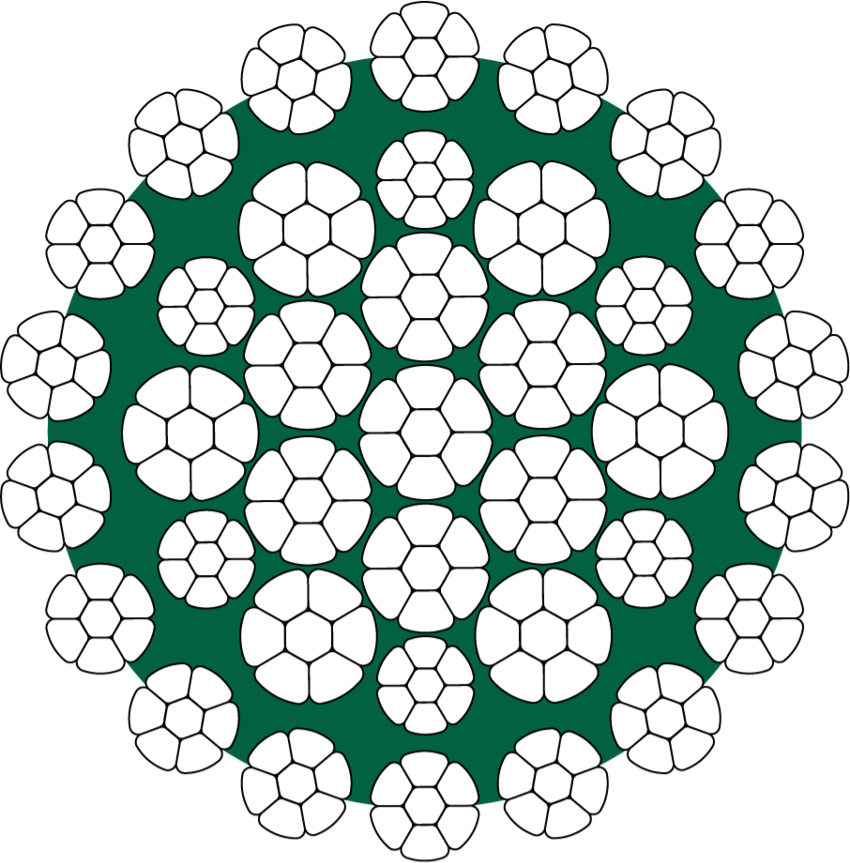

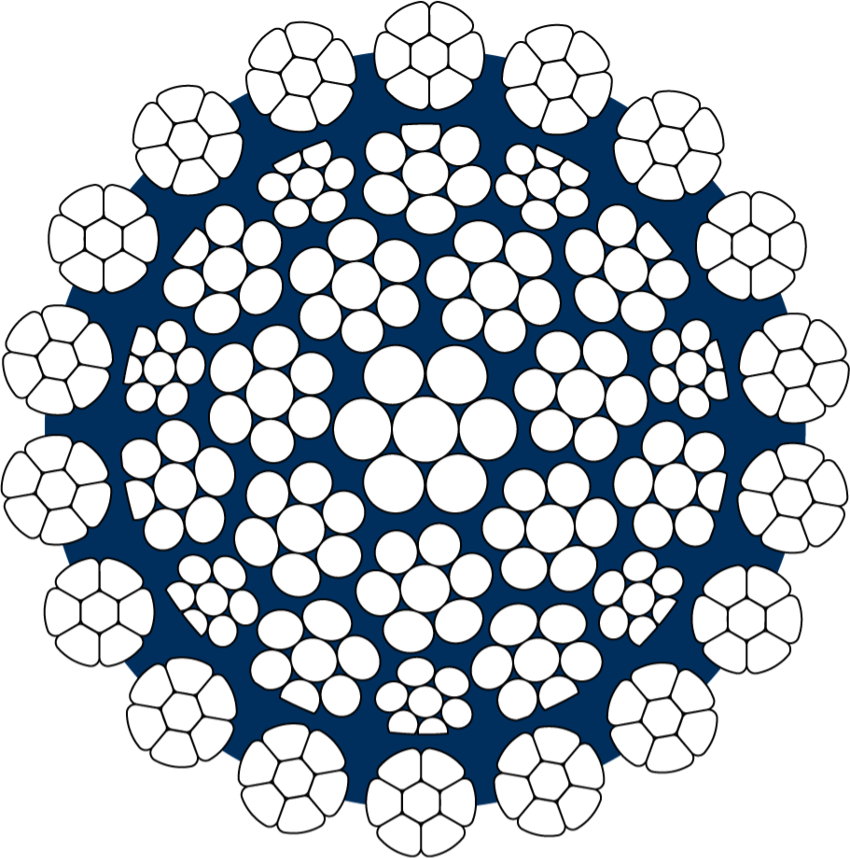

| number of outer strands | 18 | |||

|---|---|---|---|---|

| number of wires | 259 | |||

| number of outer-load bearing wires | 126 | |||

| average fill factor | 0,716 | |||

Overview

- Tolerance on diameter: (EN: +0%; +5%)

- Temperature range of use: –50°C to +100°C (-58°F to +212°F)

- Temperature range of use for option PPI: -50°C to +80°C (-58°F to +176°F)

- Option PPI – only available for diameter ≥ 13mm

- Available in ordinary lay and Lang‘s lay

- Available in right-hand and left-hand

- Available in galvanized and ungalvanized

Properties

- No Swivel

- Lubricated

- Compacted

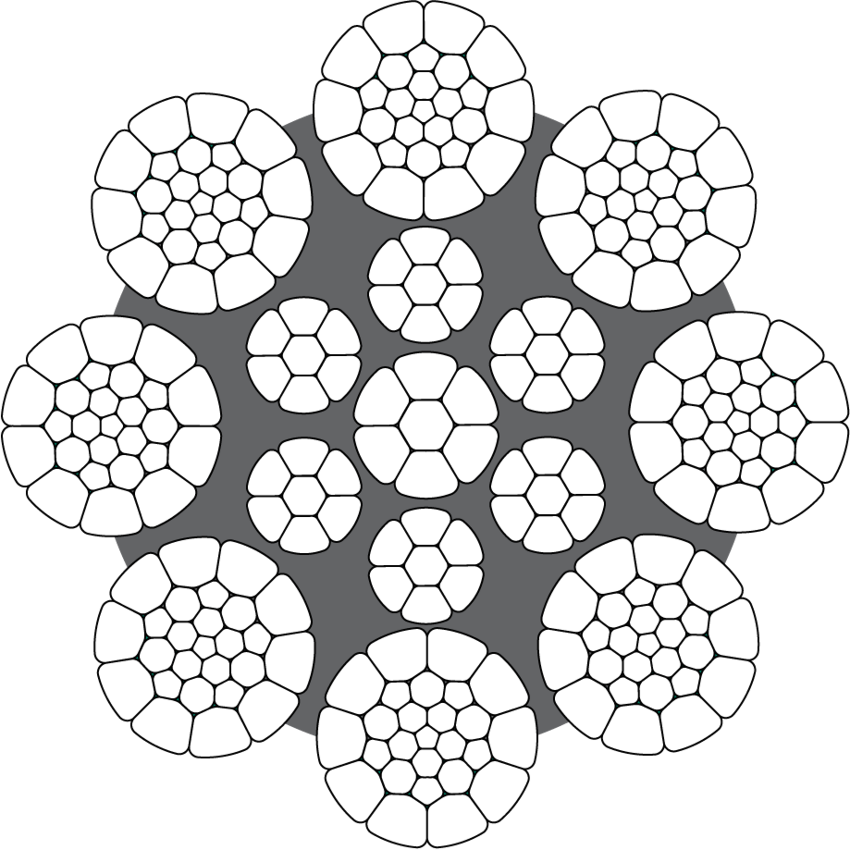

| number of outer strands | 8 | |||

|---|---|---|---|---|

| number of wires | 259 | |||

| number of outer-load bearing wires | 126 | |||

| average fill factor | 0,716 | |||

Overview

- Temperature range of use: –50°C to +75°C (-58°F to +167°F)

- Suitable for multilayer spooling in Lang‘s lay

- Available in ordinary lay and Lang‘s lay

- Available in right-hand and left-hand

- Available in galvanized and ungalvanized

Properties

- Swivel

- Lubricated

- Compacted

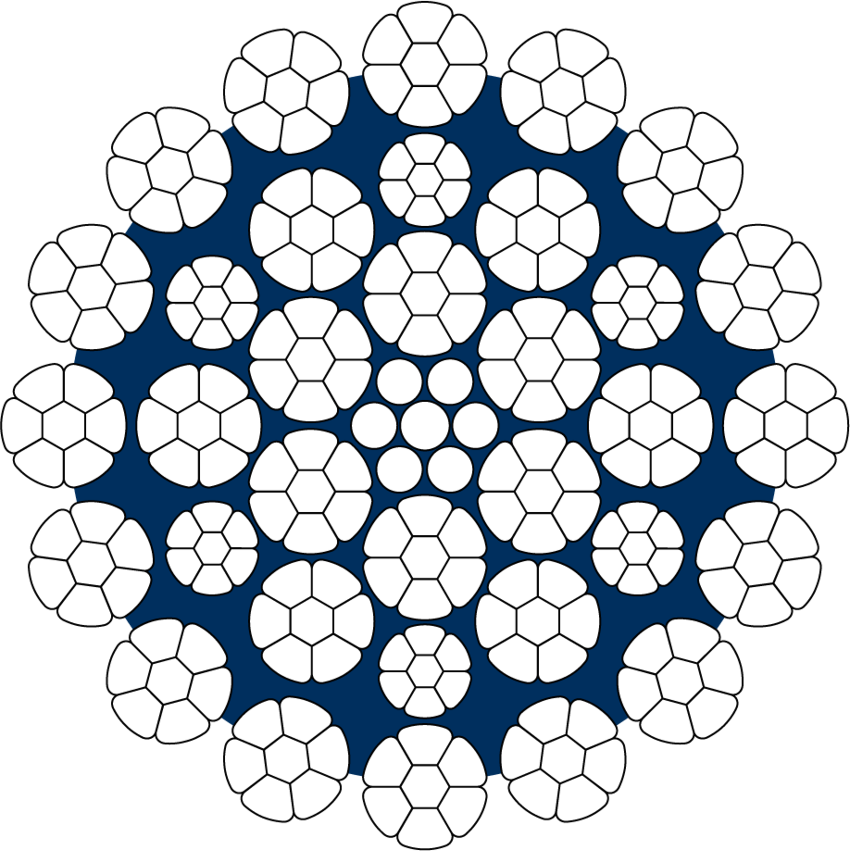

| number of outer strands | 16 | |||

|---|---|---|---|---|

| number of wires | 245 | |||

| number of outer-load bearing wires | 112 | |||

| average fill factor | 0,730 | |||

| Average nominal metallic area factor C | 0,573 | |||

Overview

- Temperature range of use: –50°C to +75°C (-58°F to +167°F)

- Suitable for multilayer spooling in Lang‘s lay

- Available in ordinary lay and Lang‘s lay

- Available in right-hand and left-hand

- Available in galvanized and ungalvanized

Properties

- Swivel

- Lubricated

- Compacted

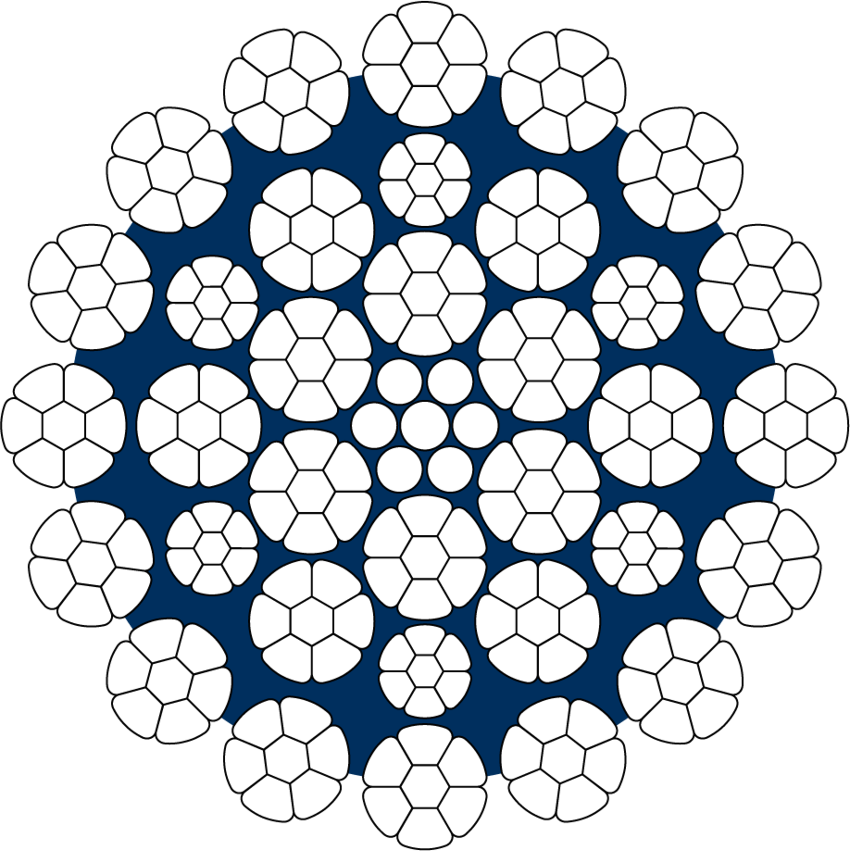

| number of outer strands | 16 | |||

|---|---|---|---|---|

| number of wires | 245 | |||

| number of outer-load bearing wires | 112 | |||

| average fill factor | 0,716 | |||

| Average nominal metallic area factor C | 0,562 | |||

Overview

- Temperature range of use: –50°C to +75°C (-58°F to +167°F)

- Suitable for multilayer spooling in Lang‘s lay

- Available in ordinary lay and Lang‘s lay

- Available in right-hand and left-hand

- Available in galvanized and ungalvanized

Properties

- Swivel

- Lubricated

- Compacted

| number of outer strands | 18 | |||

|---|---|---|---|---|

| number of wires | 280 | |||

| number of outer-load bearing wires | 126 | |||

| average fill factor | 0,720 | |||

| Average nominal metallic area factor C | 0,565 | |||

| Average spin factor (*N/MM²) | 0,82 (1960)* / 0,80 (2160)* | |||

Overview

- High breaking load and good resistance against crushing. Hoisting rope in multiple part reeving for smaller lifting heights as well as for twin hoist systems with left and right hand lay ropes for greater lifting heights.

- Temperature range of use: –50°C to +115°C (-58°F to +239°F)

- Suitable for multi-layer spooling in Lang‘s lay

- Available in ordinary lay and Lang‘s lay

- Available in right hand and left hand

- Available in galvanized and ungalvanized

Properties

- No Swivel

- Lubricated

- Compacted

- Plast Rope

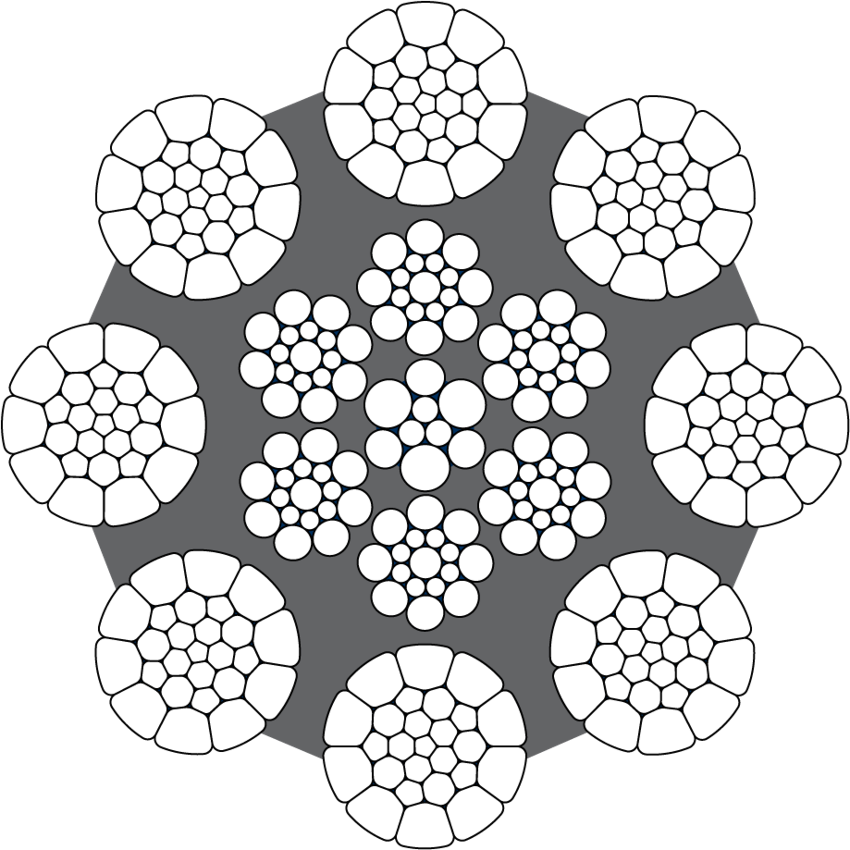

| diameter range (mm) | 8 | 9 - 24 | 25 - 48 | 50 - 72 |

|---|---|---|---|---|

| rcn | 09 | 09 | 09 | 11 |

| number of outer strands | 8 | 8 | 8 | 8 |

| number of wires | 259 | 319 | 327 | 367 |

| number of outer-load bearing wires | 208 | 208 | 208 | 248 |

| average fill factor | 0,664 | |||

| Average nominal metallic area factor C | 0,512 | |||

| Average spin factor (*N/MM²) | 0,87 (1770)* / 0,86 (1960)* / 0,86 (2160)* | |||